Technical

With our proprietary perforation technology, we consider that perforated materials have infinite possibilities in various fields, such as food, medical supplies, miscellaneous goods, architecture, transportation, agriculture and industry, and provide planning and manufacturing of products that meet customers’ requests together with customers.

Perforation technology (contract processing)

We use two kinds of perforation methods: a hot needle perforation method using general heated needles (B Kikou ) and our proprietary fusing perforation method using fusing energy (Kikou).

Fusing perforation … Three models: Kikou I, II and S, Pore size: 100 μ to 500 μ

Hot needle perforation … Five models for each pattern of B Kikou, Pore size: 250 μ to 1.5 mm

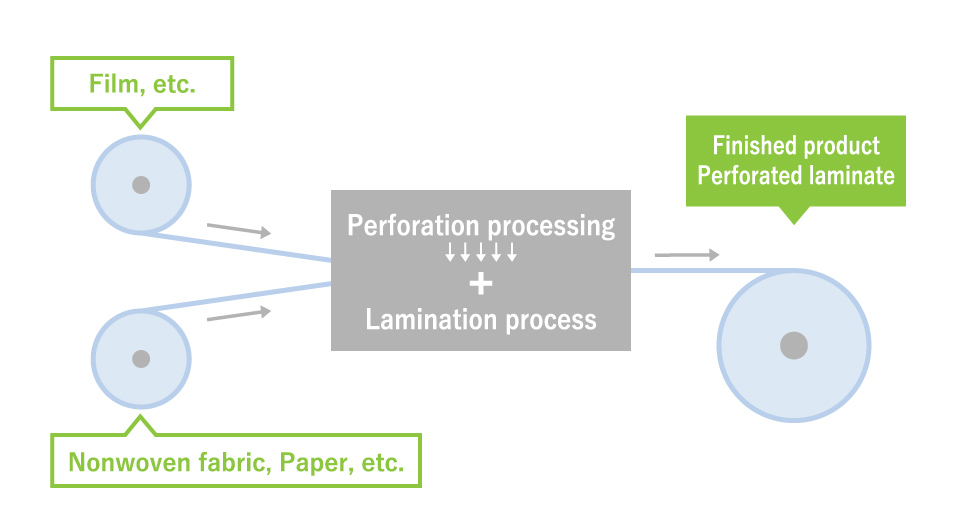

K Marimo technology (contract processing)

*Our proprietary technology

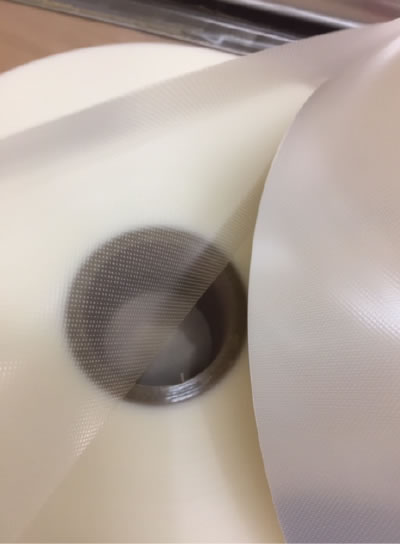

Materials perforated all over are laminated. Composite materials (with nonwoven fabric, paper, etc.) having [air permeability, water permeability or thermal sealing performance] can be obtained.

Materials are bonded with the resin melted during perforation processing. This is a technology for laminating materials without any adhesive or the like.

Lamination processing technology

Product name <K Marimo processing>

Film perforation and lamination (two-layered, three-layered, thermal lamination)

Selection of materials

Nonwoven fabric × Unstretched film (sealant layer acceptable)/All over perforation and lamination

Paper × Unstretched film (sealant layer acceptable)/All over perforation and lamination

Feature

Materials for outer or inner wrapping (food, medical supplies, miscellaneous goods) having water permeability, air permeability and breathability

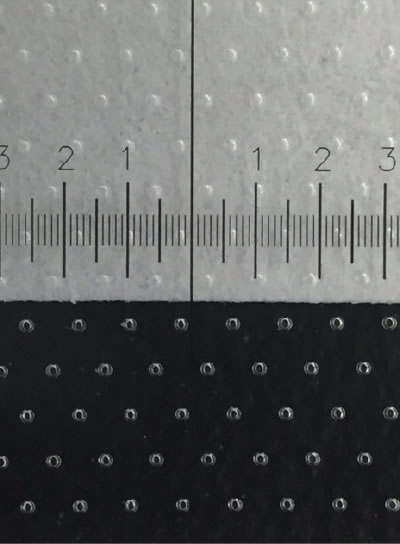

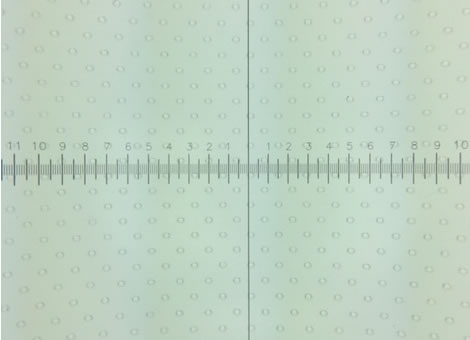

Microporous film having pore sizes of 150 μ to 500 μ (all over perforated and laminated) for fusing sheet perforated all over

* Sanitary materials that have no odor and cause no deterioration or exfoliation by chemicals because no binding agent is usedImage of K Marimo process

-

-

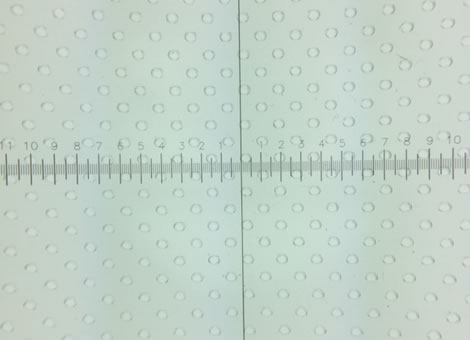

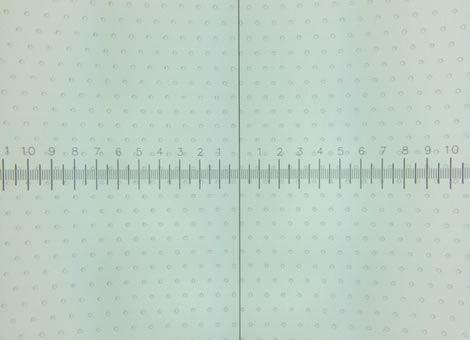

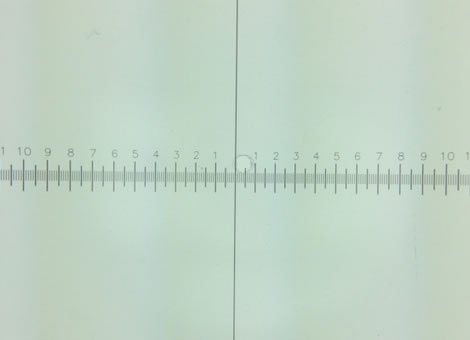

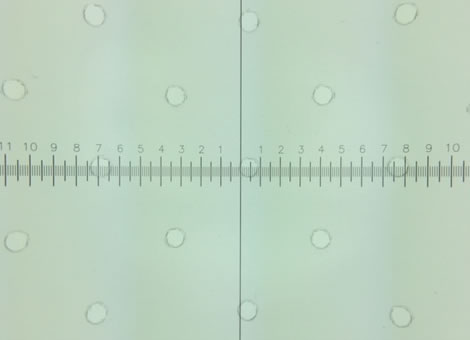

The unit of figures is millimeters. (Marked in 0.1 millimeter increments.) -

Product that was slit after perforation -

Application examples of perforation processing/perforated films

- Food field

-

Freshness retention bags for vegetables/fruits

Wrapping materials for bread

Drip sheet for fresh fish/meat

Top seals/films for natto

Packaging materials for Japanese/western confectionery

Packaging materials for frozen foods

- Medical field

-

Sterile bags

Hemostatic pads

Materials for adhesive bandages

Patch sheets

- Others

-

Wrapping materials for desiccant

Wrapping materials for flowers

Materials for gardening

Soundproof materials

Packaging materials for toys

These products provide air permeability, water permeability, gas venting, releasability and moisture condensation proofness, etc. If you have any request for other applications of our processing technology, please feel free to contact us. We will conduct planning and manufacturing together with you.

Introduction of products

Kikou ® series

-

KikouⅠ -

KikouⅠI -

KikouS

B Kikou ® series

<B Kikou ®> products can have endless partial perforations in the flow direction.

-

B Kikou4 -

B Kikou5 -

B Kikou9 -

B Kikou10

Specifications of Kikou ®

| Category | Name | Pattern | Pore size | Number of pores/㎡ | Aperture ratio | Maximum processing effective width |

|---|---|---|---|---|---|---|

| Fusing perforation | KikouⅠ |  |

200μ ~300μ |

890,000 | 2,8% ~6,3% (x=4,4%) |

1,050㎜ |

| KikouⅡ |  |

350μ ~450μ |

620,000 | 5,9% ~9,8% (x=7,8%) |

1,100㎜ | |

| Kikou-S |  |

100μ ~200μ |

1,786,000 | 1,4% ~5,7% (x=3,2%) |

1,200㎜ | |

| Hot needle perforation | B Kikou-1 |  |

1,5㎜ | 20,000 | 3,5% | 1,050㎜ |

| B Kikou-4 |  |

0,8㎜ | 3,200 | 0,16% | ||

| B Kikou-5 |  |

0,2㎜ ~0,25㎜ |

20,000 | 0,06% ~0,1% (x=0,08%) |

||

| B Kikou-9 |  |

0,8㎜ | 2,500 | 0,13% | ||

| B Kikou-10 |  |

0,7㎜ | 40,800 | 1,6% |