テクニカル情報TECHNICAL

弊社の技術により、有孔加工を施された資材は食品、医療、雑貨、建築、輸送、農業、産業等あらゆる分野において、無限の可能性があると位置付け、お客様のご要望に沿った商材をお客様と共に、企画・制作させて頂きます。

有孔技術(受託加工)

プラスチックフィルム単体及び複合に孔を開ける技術です。

弊社では開孔技術として一般的な針に熱をかけて開ける熱針方式(B機孔)と、弊社独自の溶射エネルギーにより開孔する溶孔方式(機孔)の二種類の方法があります。

溶 孔・・・機孔Ⅰ・Ⅱ・Sの3機種 孔径 100μ~500μ

熱針穿孔・・・B機孔各パターン5機種 孔径 250μ~1.5mm

弊社では開孔技術として一般的な針に熱をかけて開ける熱針方式(B機孔)と、弊社独自の溶射エネルギーにより開孔する溶孔方式(機孔)の二種類の方法があります。

溶 孔・・・機孔Ⅰ・Ⅱ・Sの3機種 孔径 100μ~500μ

熱針穿孔・・・B機孔各パターン5機種 孔径 250μ~1.5mm

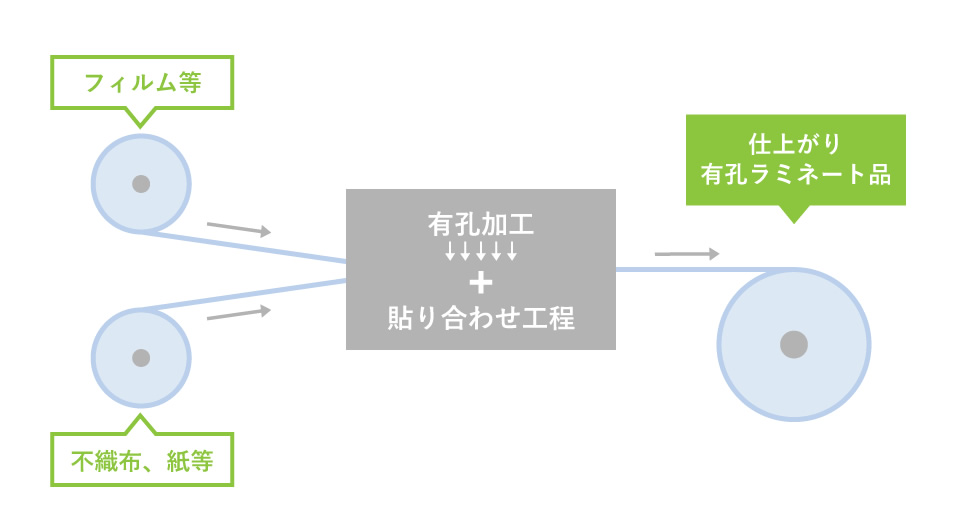

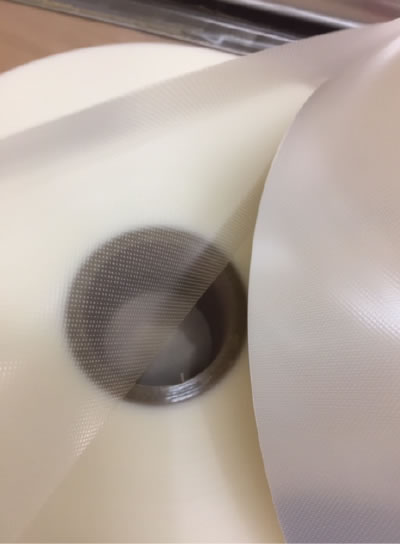

Kマリモ技術(受託加工)

※自社独自技術です。

異材との複合加工です。

有孔加工も施された全面有孔貼合技術です。(不織布、紙等)【通気・通水・熱シール性】が付与される複合材となります。

有孔加工した際の解けた樹脂で接着しますので、接着剤等は一切使用しない張り合わせ技術です。

有孔加工も施された全面有孔貼合技術です。(不織布、紙等)【通気・通水・熱シール性】が付与される複合材となります。

有孔加工した際の解けた樹脂で接着しますので、接着剤等は一切使用しない張り合わせ技術です。

貼り合わせ加工技術

熱ラミネーション(全面積穿孔貼り合わせ)

品名<Kマリモ加工>

◉フィルム穿孔ラミネーション(2層、3層、熱貼加工)

選材

○不織布×無延伸フィルム(シーラント層OK)・全面積穿孔ラミネート加工

○ 紙 ×無延伸フィルム(シーラント層OK)・全面積穿孔ラミネート加工

特徴

・通水性、通気性、呼吸性が可能な外装・内装用(食品、医療、雑貨)資材

・全面有孔溶着のシート化150μ~500μ径微孔フィルム(全面積穿孔接着)

※バインダー剤不使用で臭気が残らない、薬品劣化剥離がない衛生資材Kマリモ工程イメージ

-

-

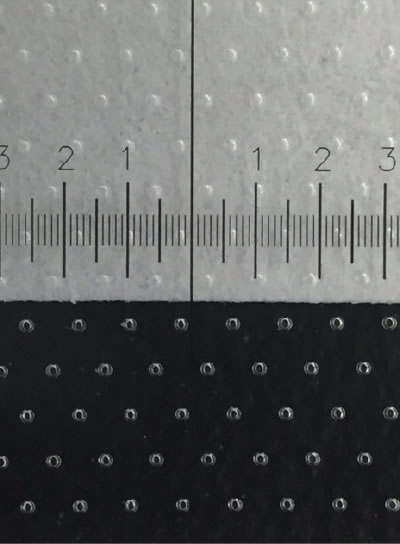

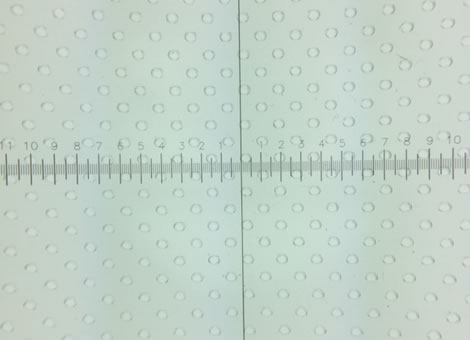

数字の単位はミリです。(1目盛は0.1ミリとなります。) -

有孔後スリット加工品例 -

有孔加工・有孔フィルムの用途例

- 食品分野

-

野菜・フルーツ鮮度保持袋

パン用包材

鮮魚・肉ドリップシート

納豆用トップシール・被膜

和菓子・洋菓子包装資材

冷凍食品包装資材

- メディカル分野

-

滅菌袋

止血パット

絆創膏資材

パッチシート

- その他

-

乾燥剤用包材

花用包装資材

園芸用資材

防音資材

玩具包材

主な内容としましては、通気、通水、ガス抜き、離型性、結露防止などが挙げられますが、上記以外にも、弊社加工技術によりお役に立てる案件等ございましたらお気軽にお問い合わせください。お客様と共に企画、製作させて頂きます。

製品紹介

機孔®シリーズ

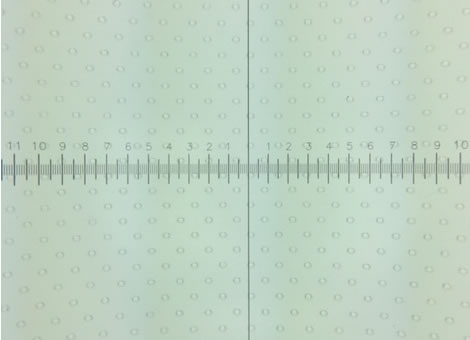

独特の溶孔方式で穿孔した有孔フィルムの総称で、当社創業の基礎となった製品です。

熱針方式とは異なる有孔加工なので抜き滓の発生はありません。孔と孔のピッチが他に類を見ない微少ピッチであることに加えて、均一な孔の大きさ、微かな溶環が相俟って美麗な外観を呈します。ラップ材等として単品使用されるのは勿論ですが、複合材として広範囲に利用されています。

この<機孔®>シリーズには<機孔Ⅰ><機孔Ⅱ><機孔S>の3アイテムがあります。

-

機孔Ⅰ -

機孔ⅠI -

機孔S

B機孔®シリーズ

熱針方式で穿孔した有孔フィルムで、孔数・孔径・孔ピッチ等を組み合わせパターン化した数種類のアイテムを揃えております。当社ではこのシリーズを<B機孔®>と総称しています。単品で呼吸機能通水機能を持った包材等として採用され、また複合フィルムの一方の基材として利用されます。特殊機能を持った新製品として甦ります。

なお、この<B機孔®>製品は流れ方向に対してエンドレスの部分有孔が可能です。

なお、この<B機孔®>製品は流れ方向に対してエンドレスの部分有孔が可能です。

-

B機孔4 -

B機孔5 -

B機孔9 -

B機孔10

機孔®諸元一覧表

| 区分 | 名称 | パターン | 孔径 | 孔数/㎡ | 開口率 | 最大加工 有効巾 |

|---|---|---|---|---|---|---|

| 溶融 穿孔 |

機孔Ⅰ |  |

200μ ~300μ |

890,000 | 2,8% ~6,3% (x=4,4%) |

1,050㎜ |

| 機孔Ⅱ |  |

350μ ~450μ |

620,000 | 5,9% ~9,8% (x=7,8%) |

1,100㎜ | |

| 機孔-S |  |

100μ ~200μ |

1,786,000 | 1,4% ~5,7% (x=3,2%) |

1,200㎜ | |

| 熱針 穿孔 |

B機孔-1 |  |

1,5㎜ | 20,000 | 3,5% | 1,050㎜ |

| B機孔-4 |  |

0,8㎜ | 3,200 | 0,16% | ||

| B機孔-5 |  |

0,2㎜ ~0,25㎜ |

20,000 | 0,06% ~0,1% (x=0,08%) |

||

| B機孔-9 |  |

0,8㎜ | 2,500 | 0,13% | ||

| B機孔-10 |  |

0,7㎜ | 40,800 | 1,6% |